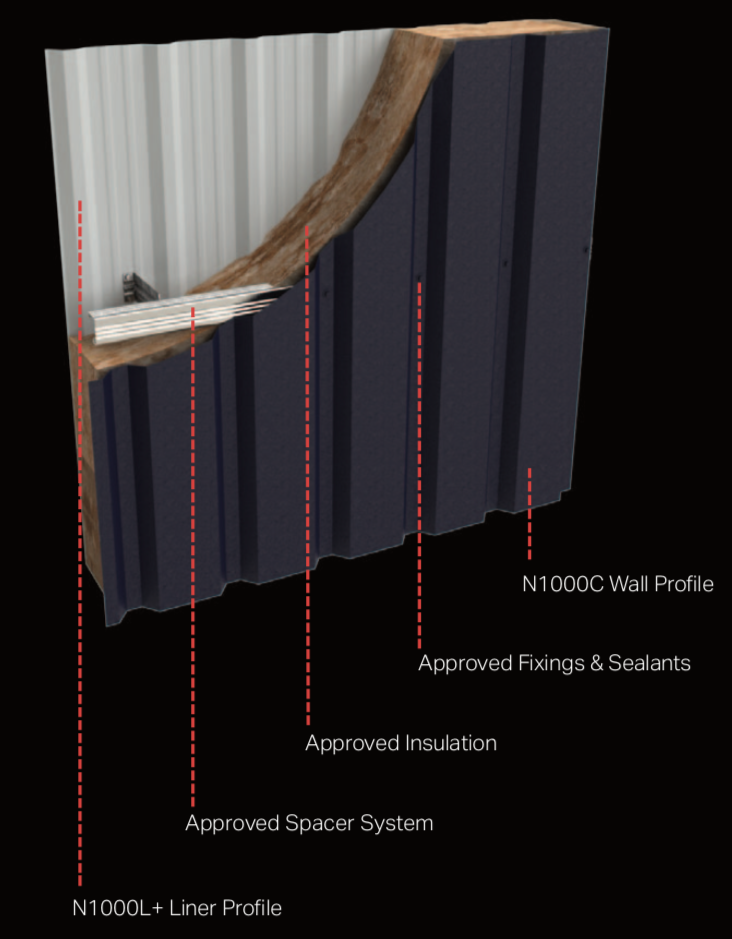

The PRX-WS®-01 offers a tailor-made built up wall system combining high performance external finishes, A1 Non- combustible Insulation and a light weight liner profile alongside industry leading Protex® Approved Suppliers to offer complete 25 Year System Guarantee.*

Got a question? Email our technical team at info@firth-steels.co.uk or call +44(0)1484 405940

TECHNICAL LIBRARYThe system depth can be configured to meet the project specific thermal, acoustic and fire performance with enhanced system designs available.

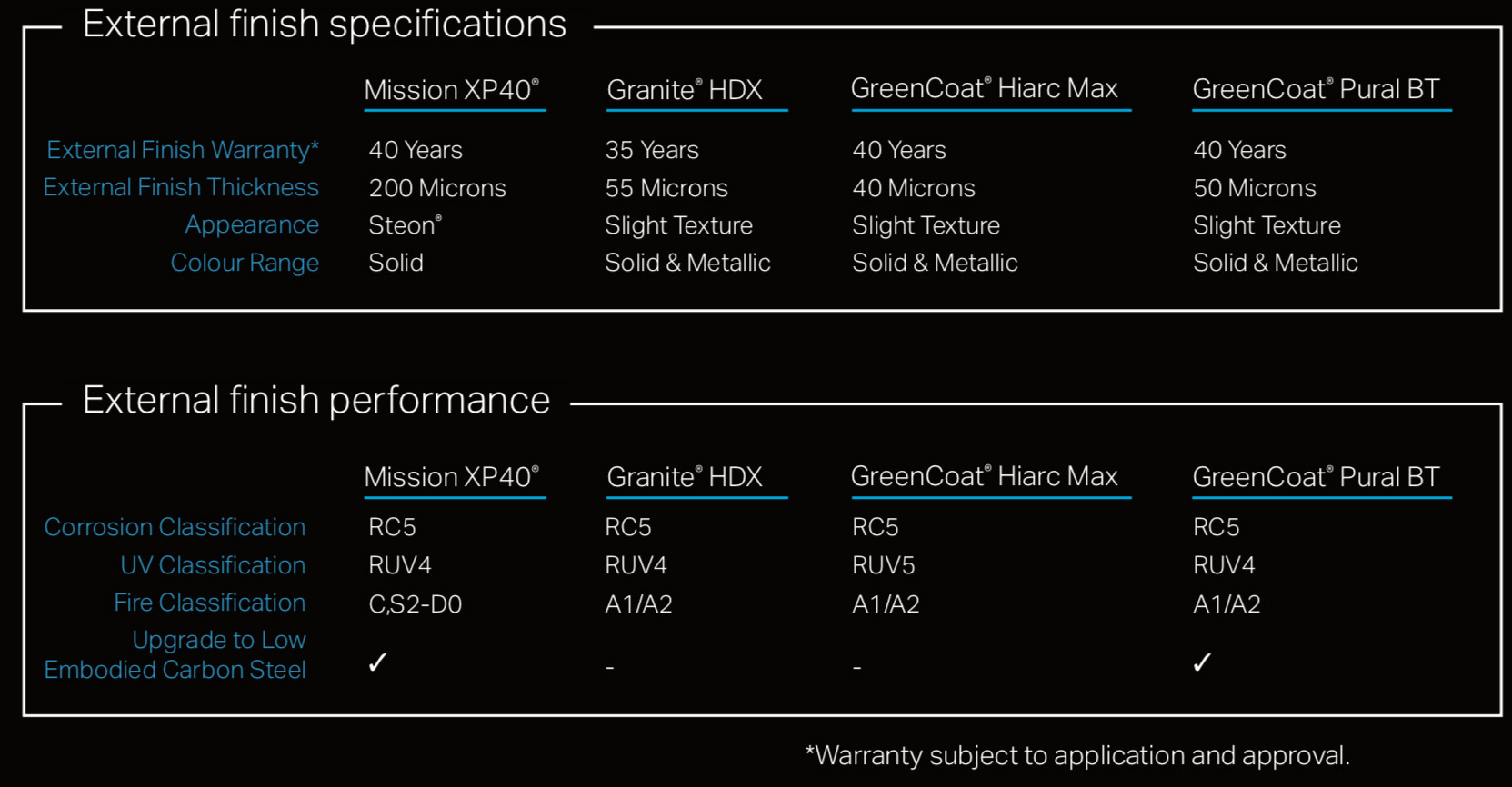

The external N1000C Wall Profile, vertically orientated, can be specified in a range of high performance external finishes, offering external finish warranty periods up to 40 Years. The range of embossed, textured or smooth external finishes offer a solution to cover a full range of building envelopes. The external finish can be specified in an A1 Rated finish to offer a complete Non- Combustible Wall System.

The PRX-WS®-01 System can be upgraded to the PRX-FWS-01-E240/I15 Fire Wall System. The system has been tested to BS476 Part 22 to offer 240 Minutes Integrity and 15 Minutes Insulation.

The N1000L+ Liner profile offers an economical solution incorporating a19mm light weight profile into the system. The N1000L+ Profile is available in Bright White Liner as standard with an A1 Fire Classification.

The Protex® Approved components can be sourced directly through our industry leading Protex® Approved supply partners to ensure the highest levels of product performance and support.

The Protex® Systems have been tested and certified by world leading testing houses including Warrington Fire, BRE Global and to Loss Prevention Certification Board (LPCB). The internationally respected Loss Prevention Standards known as LPS gives confidence that the systems comply with the LPC Design guide for the external fire protection of buildings.

The LPS1181 Series of standards were developed by key stakeholders including ABI (Association of British Insurers), developers, building owners and trade associations for the purpose of property protection. The Protex® Systems have been tested and certified to the standard LPS1181 Part 1: Issue 1.2 – Series of Fire Growth Tests for LPCB Approval and Listing of Construction Product Systems. Part 1: Requirements and Tests for Built-up Cladding and Sandwich Panel Systems for use as the External Envelope of Buildings.

The Protex® PRX-RS® Roof Systems and PRX-WS® Wall Systems are certified and listed on Red Book Live. Certification to LPS1181-1 Grade EXT-B can be specified utilising approved components from our enhanced range of approved suppliers.

The LPCB Red Book is a key reference for specifiers, regulators, designers and end users of fire and security products and services. For systems to be listed in the Red Book they require independent experts to robustly check that it delivers and will continue to deliver the performance expected.

The Protex® Systems certification and documentation can be found via the RedBook Live website through certificate number 1611a.

The external finish can be specified in an A1 Rated finish to offer a complete Non- Combustible Wall System

The mission we were set was to bring a solution to market that extended the life and performance of the building envelope. XP40® was developed from the ground up with every additional layer rigorously tested to ensure optimum unrivalled performance. Everything from the material substrate, to the configuration of the primer coat, right through to the external finish that is uniquely embossed with the Steon® emblem has allowed for the evolution of organically coated steel in way that has not been seen in a generation.

Mission XP40® brings a newlevel of performance that not only extends the life of your investment but reduces your carbon footprint at the same time. Tomorrow’s external finish for today.

Granite® HDX by Arcelor Mittal is a high performing pre-painted external finish ideally suited for buildings requiring high levels of corrosion resistance and colour stability. The external finish is manufactured to perform, endure and remain colour stable even in aggressive environments. The external finish has a lightly grained appearance which enhances the surface hardness.

Our unique partnership with SSAB enables us to offer a fresh new approach to the external coating options available for your building. The revolutionary GreenCoat® range gives creative and innovative options for buildings, whilst using the most sustainable colour coated steel products on the market. GreenCoat® offers an innovative; eco-conscious colour coated steel solution for the building industry and has been developed specifically to provide building envelopes and internal solutions with superior aesthetics, unrivalled performance and above all designed with the future in mind.

GreenCoat® Pural BT is available in regular and matt finishes and offers a wide range of colors inspired by Nordic nature. It uses a patented bio-based coating having Swedish rapeseed oil instead of traditional fossil oil in the paint, which is unique on the market.

GreenCoat® Hiarc Max colour coated steel is available in regular and matt finishes. It is available in a wide range of colors inspired by Nordic nature. GreenCoat® Hiarc Max is extremely durable (RC5 and Ruv5) and is specifically developed for Roof & Wall applications. GreenCoat® Hiarc Max possesses excellent weather resistance properties and offers extremely good corrosion resistance. The product is well suited for buildings in the harshest environments, like those near a coastline.

Fill in the form below and our team will get right back to you.

We work with industry leading partners to create a site assembled system from a catalogue of verified, tested, and approved components. Our carefully curated directory of Protex® Approved Suppliers and their specific product ranges, provides excellent customer service and specialist technical support. We will collectively work with the design team through to the site team to ensure the project runs efficiently throughout its life span.

Each component within the system can be uniquely specified to suit the individual projects requirements. Sustainability, fire, thermal and acoustic performance combined with a buildings use, location and surrounding environment will all impact the projects design requirements.

The ability for the contractor to maintain established relationships with trusted organisations, ensures a competitive edge and improved efficiency on site.